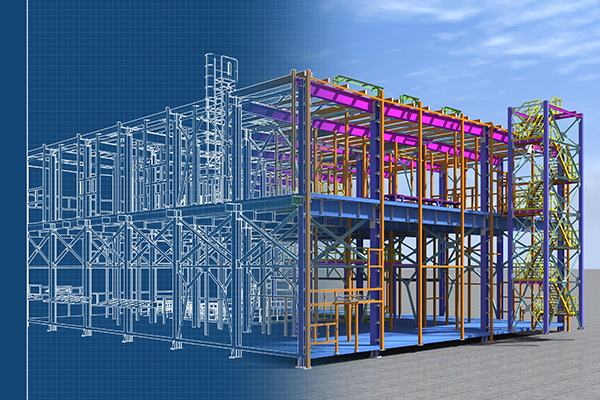

Preventative maintenance (PM) is the service regularly performed on a piece of equipment to lessen the likelihood of it failing. Planned and performed during regular business hours while the equipment is still working, PM helps make sure resources are accessible, while decreasing operating costs and the chance of machinery failing unexpectedly.

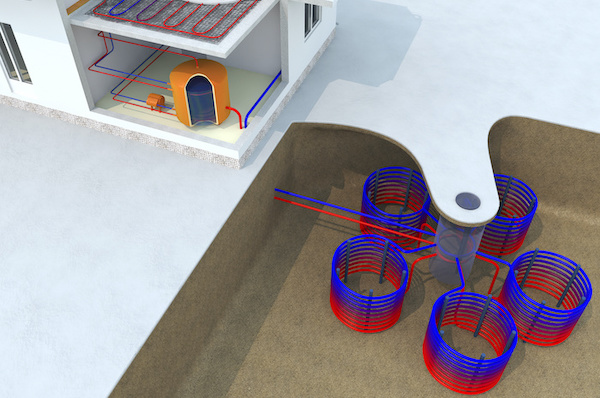

Having a PM schedule in place is the best way to make sure that maintenance checks occur at the necessary time for each piece of equipment. Common equipment types and corresponding maintenance items can include cleaning an HVAC system’s drain pan and coils, checking the piping connections, valves, and gauges on a water pump, and inspecting the physical and mechanical condition of a transformer. While schedules will differ depending on the company, PM should focus on cleaning, lubrication, and correcting deficiencies found through testing and inspections. Instead of taking a reactive approach, putting a PM system in place will reduce costs due to damaged equipment and will maintain operating efficiency over time.

To gain more insight about how to effectively implement preventative maintenance, download our white paper, “Preventative Maintenance: Keep Your Building Running Successfully,” or email us at mail@bhbinc.com.