The demand for more sustainable buildings is growing faster than ever. The construction industry has been forced into making more energy-conscious choices in their equipment selection and operation of systems. While these practices are commonly integrated into today’s buildings, there are differences in how each facility type approaches these decisions.

When selecting building systems, a university or college’s focus typically falls on maintenance consistency and life expectancy. Unlike other facilities, universities plan to be tenants for the lifetime of a building. In comparison, other developers may be designing a space they only occupy for a few years before passing it onto new tenants. During the design process, they may be more cost-driven in their selection of equipment than prioritizing a system’s longevity.

“Most institutions are building 100-year buildings. They want to know that what they buy is going to last,” says Ian Bost, Principal, and Senior Mechanical Engineer.

Often, universities prefer to use manufacturers they are familiar with. They can lower operation and maintenance costs if they already have the repair supplies and maintenance staff familiar with servicing their equipment. As the design team, our engineers weigh various options before determining the best fit for a project. This includes tracking new technologies and their success on the market.

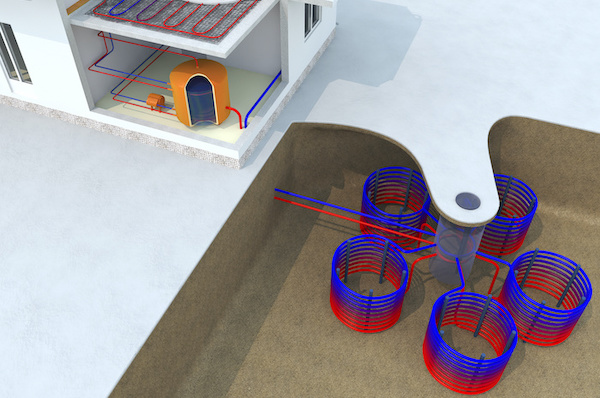

BHB mechanical engineers Ian Bost and Kirk Plum followed the success of bipolar ionization, a technology that reduces the outside air required by charging particles in the air to clean it. Since K-12 facilities with limited maintenance resources were successfully using this technology on their equipment, BHB felt confident implementing this on higher education campuses.

Texas Christian University, Sadler Hall

This project renovated an existing office on campus into a mixture of new classrooms, offices, and lounge spaces. Since classrooms hold more people in a single space, windows would have to be removed so the existing air handling units could be reused. As a solution, BHB implemented bipolar ionization to reduce the outside air load for the space and allow the building to keep visible windows within each classroom.

University of North Texas, Curry Hall

The windows on the first and second levels of Curry Hall had been blacked out to allow the existing air conditioning units to keep up with the external heat gain. By using bipolar ionization, our team was able to reduce the outside air load for the building which allowed us to replace the existing windows with a clear, energy-efficient option. The solution will transform the classrooms into bright, clean spaces for students to learn.

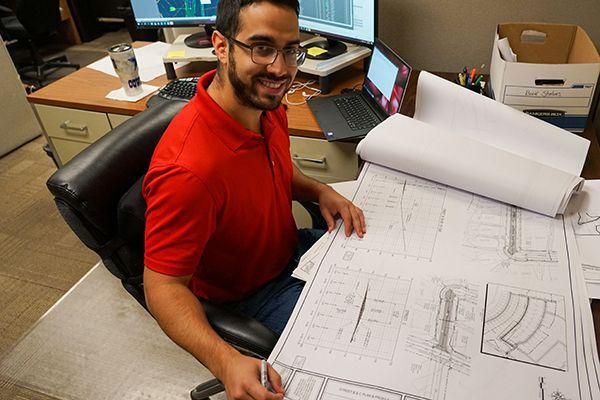

In both cases, BHB implemented new, energy-efficient systems to meet our client’s needs. “BHB always tries to balance giving the owner the best possible systems, while not just giving them the gold-plated product. We give them what they need” says Kirk Plum, Mechanical Engineer.

As the first engineering firm in the metroplex to become a member of the 2030 Challenge, BHB has proven its commitment to selecting sustainable design solutions to meet the unique needs of every client.

To learn more about our services and energy-efficient design efforts, please reach us at mail@bhbinc.com.