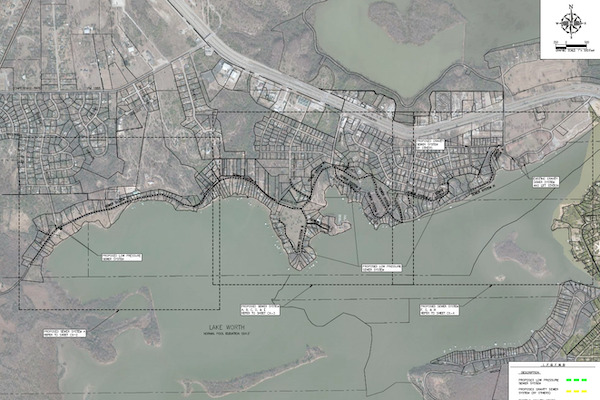

In 2016, BHB’s engineering team provided a campus assessment for the mechanical equipment at Southwestern Baptist Theological Seminary (SWBTS) in Fort Worth, Texas. The non-profit institution noticed that unnecessary energy was being spent on the existing chilled water system, so they reached out to BHB to see what could be done to reduce energy and increase cost savings.

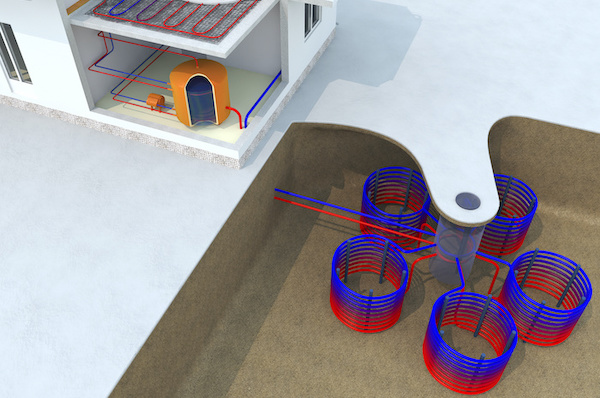

“The chilled water loop on campus had a very low Delta T (temperature difference between the supply and return water),” said Ian Bost, Senior Mechanical Engineer at BHB. “That basically meant they were spending a lot of energy moving water without an added cooling benefit. The owner wanted to see how much money could be saved on energy and the existing infrastructure, while improving the HVAC system.”

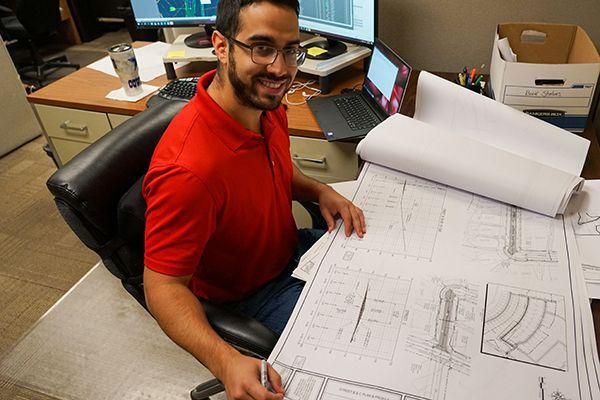

BHB began the assessment by putting together a multi-step process to review the entire system. To start, Ian and his team gathered all the information available on the building systems. Then, this information was placed into a “pipe-flo” model to determine where the chilled water was flowing and simulate how alterations affected the flow. SWBTS was then tasked with welding sample ports on the chilled water supply in each of the buildings, so that the engineers had a way of measuring the flow, temperature, and energy usage for each building. This also gave the seminary a way to measure energy usage for the future, so that the system can continue to be monitored.

“SWBTS wasn’t running out of chiller capacity, but they couldn’t flow any more water through their system,” said Ian. “Their previous approach was basing everything off of pump flow, not return water temperature. We got with them on a multi-step process where we reviewed their entire system and looked at the equipment at each building. We developed a report and a step-by-step guide to show SWBTS staff where to start and in which order to do certain changes.”

After an assessment is completed, the next steps can vary with each project. In some cases, BHB will take that assessment and make the necessary changes and updates. However, for this project, Ian and his team provided the campus with the guidelines of what needed to be done, and SWBTS took it from there to make the suggested improvements to the HVAC system.